Tel:+8618337312531

Email: sale@graphitesmold.com

News

-

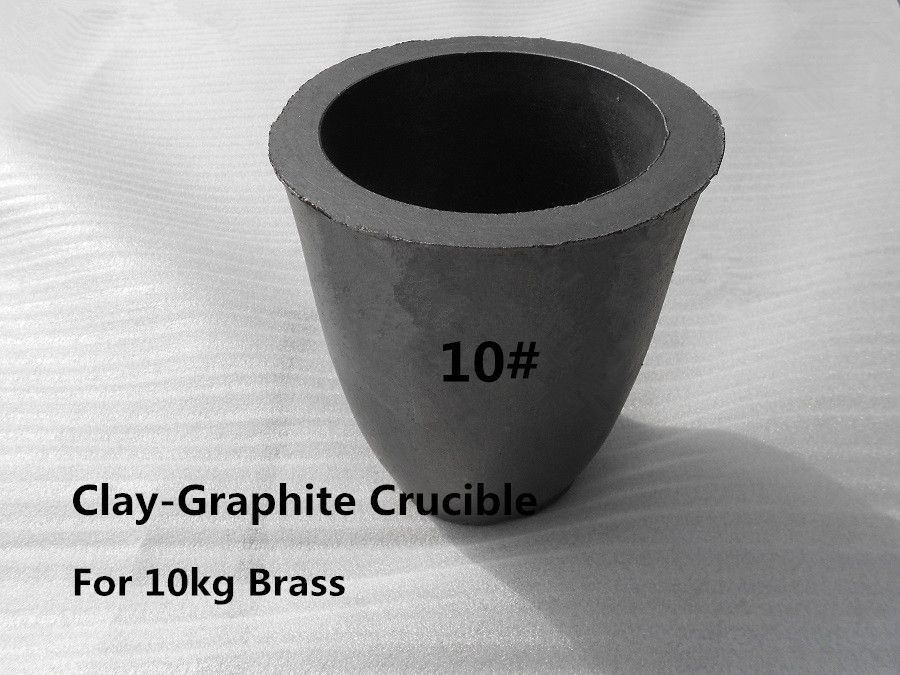

Differences Between Clay Crucibles And Silicon Carbide Crucibles

Clay graphite crucibles and silicon carbide (SiC) crucibles are two common options for industrial metal melting, but have some key differences. Clay graphite crucibles are probably the most widely used and inexpensive type. They are made...Read more -

Baking graphite crucible

After making the graphite crucible with your own hands, you need to bake it properly. This process will strengthen the structure of the crucible and give it the properties required for high-temperature experiments. It is important to ...Read more -

Fill the mold with graphite mixture

Once you have prepared the mold for your graphite crucible, you can start filling it with the graphite mixture. Graphite blends are mixtures of graphite with certain additives that improve its properties. First, you need to carefully ...Read more -

Prepare the perfect mixture of graphite powder and binder

Manufacturing a high-quality graphite crucible begins with the correct preparation of the mixture of graphite powder and binder. The main component of this mixture is graphite powder. It must have pure ingredients and a high degree of...Read more -

Structure of graphite crucible casting mold

To make a graphite crucible, you need a mold into which molten graphite is poured. Here are step-by-step instructions for creating such a form: Choose the material of the mold. To create a mold, you can use a variety of materials, suc...Read more -

Choosing the right graphite for your crucible

In order to manufacture graphite crucibles, it is important to choose the right material with the required properties. The following are the main parameters that should be paid attention to when selecting graphite materials: Temperatu...Read more -

DIY Graphite Crucible: Step-by-Step Instructions

Graphite crucibles are an integral part of many industrial processes. They are used to melt and store high-temperature materials such as metals and alloys. If you often need to use such materials, then you can make a graphite crucible wi...Read more -

What is a graphite crucible: properties and applications

Graphite crucibles have many unique properties that make them an integral part of many processes. First, graphite has high thermal stability and can withstand high temperatures without deformation. This allows the use of crucibles made o...Read more