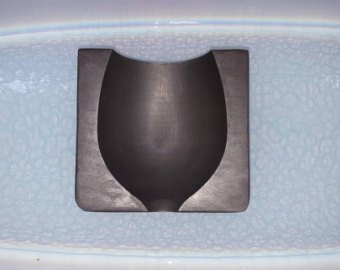

graphite mold for glass

Why glass made of graphite mold?

1. Excellent thermal and electrical conductivity

2. Low linear expansion coefficient, good thermal stability and resistance to heating shock

3. Resistant to chemical corrosion and does not easily react with most metals

4. At high temperatures (the sintering temperature of most copper-based matrix is above 800°C) the strength increases as the temperature increases.

5. Has good lubrication and anti-wear properties

6. Easy to process, good machining performance, can be made into molds with complex shapes and high precision

Summary: Graphite material has chemical stability, is not easily infiltrated by molten glass, and does not change the composition of the glass. The material has good thermal shock resistance, and its size changes little with temperature. It is a good choice for hot-bent glass.

Anyang Yurun New Materials Co., Ltd. is one of China’s professional production, research and development, sales of graphite mold manufacturers. The company is committed to providing customers with high quality graphite raw materials and precision graphite products processing. The raw materials used by our company, such as isostatic pressed graphite, molded graphite and EDM graphite, have the characteristics of high strength, good thermal shock resistance, high temperature resistance, corrosion resistance and strong oxidation resistance.