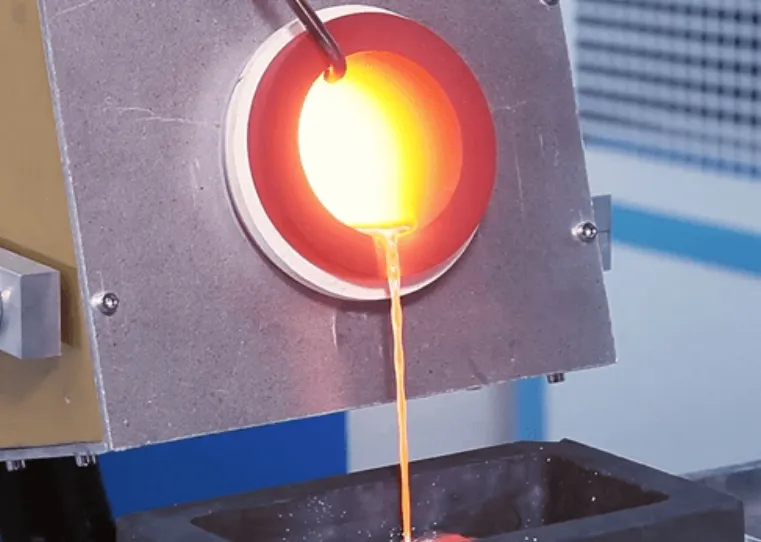

Gold melting graphite crucibles

Gold melting crucibles are usually made of high quality graphite material and can be widely used in various types of furnaces. The gold melting crucible can be used to melt gold as well as silver and other metals such as aluminum, copper, brass, iron, zinc, lead. The gold melting crucible can be loaded with gold bullion and the melting time is in the range of 5 to 10 minutes. The gold melting crucible can be properly maintained and can last for a very long time without any cracks.

The graphite crucible used for melting gold comes in different sizes from 1 kg or more.

The gold melting crucible has heat resistance, high temperature resistance and high mechanical strength. Graphite gold melting crucible has good oxidation resistance. The gold melting crucible is also capable of withstanding temperatures reaching up to 2000 degrees Celsius. The melting point can be reached in a short time, hence the melting time is shortened to save energy.

Name |

Φ1(cm) |

Φ2(cm) |

Φ3(cm) |

N (cm) |

Weight (g) |

|

1 kg graphite crucible |

58 |

46.5 |

35 |

88 |

170 |

|

2 kg graphite crucible |

68 |

57 |

43 |

108 |

280 |

|

2.5 kg graphite crucible |

68 |

58 |

43.5 |

120 |

310 |

|

3 kg graphite crucible |

72 |

66 |

51 |

110 |

390 |

|

4 kg graphite crucible |

85 |

77 |

60 |

130 |

380 |

|

5 kg graphite crucible |

100 |

88 |

69 |

132 |

680 |

|

5.5 kg graphite crucible |

104 |

92 |

69 |

155 |

860 |

|

6 kg graphite crucible |

112 |

100 |

79 |

178 |

1050 |

|

8 kg graphite crucible |

125 |

112 |

90 |

160 |

1000 |

|

12 kg graphite crucible |

150 |

134 |

100 |

210 |

1600 |

|

16 kg graphite crucible |

160 |

138 |

110 |

220 |

2000 |

|

25 kg graphite crucible |

165 |

165 |

135 |

220 |

1600 |

|

30 kg graphite crucible |

215 |

215 |

175 |

250 |

4700 |

Crucible for melting gold in the process of using at high temperatures, the coefficient of thermal expansion is small and has a certain resistance to deformation when quenched and heated.

The corrosion resistance of acid and alkali solution is high, it also has high chemical stability, and no chemical reaction occurs during the melting process.

The inner wall of the gold melting crucible is smooth, which makes all metals have a smooth finish after casting, and sticks to the inner wall of the crucible, so that the molten liquid has good fluidity and is suitable for casting into various shapes.

The gold melting crucible can also be used in melting alloy tool steel and melting non-ferrous metals and alloys due to its excellent properties.

The high density gold melting crucible has better thermal conductivity and is superior to other imported crucibles in its thermal conductivity.

The gold melting crucible has a special glaze layer and compact molding material, which greatly improves the corrosion resistance and extends the service life of the crucible.

All graphite components of the gold melting crucible are made from natural graphite, which provides very good thermal conductivity. Crucible users should remember that graphite crucibles should not be placed on a cold metal table immediately after melting to prevent destruction due to rapid cooling.

Other types of metals can undergo a smelting process in a crucible to melt gold. Such metals include silver, copper, aluminum, lead, zinc, brass and other non-ferrous metals.

The graphite gold smelting crucible can be adapted to inert atmosphere furnaces, making it suitable for high-quality smelting.

Gold melting crucibles are sold in different sizes to suit all melting ranges, from 1 kg to 5 kg and above. Different sizes can be used for different types of users, from small jewelry melting enterprise to large industrial use.

Gold melted in a gold smelting crucible is usually of high quality simply because the graphite crucible does not release any impurities despite frequent use of smelting.

Extremely Durable

The highest manufacturing standard, high density and low porosity make the crucible more durable.